In the 1960s Sunny Bank Mill began using chemical dyes to dye its wool on site, a practice which continued until the Mill closed and then the tools and records of the dyeing department were placed in the archive.

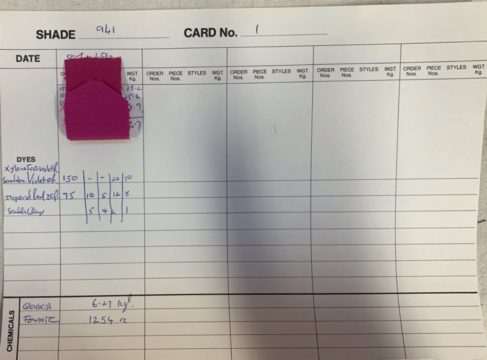

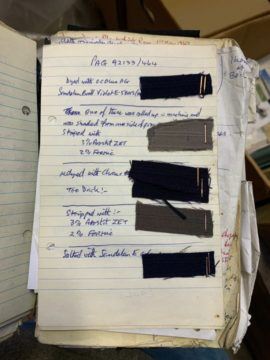

Dyeing was a complex process that relied on incredibly exact measurements. There are 5,000 dye recipe cards, many of them contain different shades which to the untrained look exactly the same but which the experts in the dye department had laboured over to produce the exact shade of navy blue or black they wanted. Admittedly some of the colours produced in the 1990’s are very obviously unique, my favourite being fantastic shade of bright pink made in 1992. The dye department combined dye chemicals brought from large dye manufacturers, to ensure the right colour the measurements of dye had to be exact. Those working in the department were undoubtedly excellent chemists their notebooks show careful trial and error to get the exact shade.

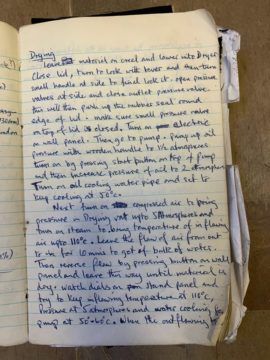

The dyeing process was more than creating the dye itself. They also had to consider how to get the dye to stay in the wool once it had been treated. The dye department achieved this mainly by using Glauber salts and Formic acid which ensured the colour didn’t bleed out of the fabric, after all no one wants to buy a suit that changes colour every time its washed. They also had the problems that have faced every company since the beginning, that of keeping up with technological developments and managing technical problems. The same notebooks that record the development of specific shades of dye also contain careful notes on how to actually use the apparatus in the process of dyeing. The archive also contains dozens of instruction manuals for everything from portable pH testers to the new computer system.

The dye department was clearly a fascinating place full of brilliant people from the chemist creating the right dye shade and pairing it with the right chemical mixture, to the engineer that allowed the chemicals to be added to the wool and even including those responsible for sourcing the chemicals and technology to make it all possible. By Hannah Fay, MA History student from University of Leeds on placement at Sunny Bank Mills Archive.

Back To Blog Next (Volunteer weaving experience) Prev (Springbank Year 5 WW1 workshop display)Tags

Museum & Archive Arts & Culture General